How Fabricated Steel Angle can Save You Time, Stress, and Money.

Wiki Article

The Best Strategy To Use For Steel Fabrication Process

Table of ContentsThe Ultimate Guide To Steel Fabrication Apprenticeship3 Easy Facts About Steel Fabrication Apprenticeship DescribedUnknown Facts About Steel Fabrication ApprenticeshipNot known Facts About Fabricated Steel Angle

Each category has its very own selection of procedures utilized in the process of metal fabrication, or it can be just a single procedure entirely. Right here are three major categories of metal construction: Structural. Primarily covers metal construction as a part of the structure procedure, supplying metal parts to be made use of in different large-scale construction initiatives, such as buildings, stores, high-rises, and more.As the name suggests, this primarily covers the commercial products, designed to be made use of by consumers straight, be it appliances, vehicles, or another thing entirely. fabricated steel angle. Industrial. Focuses on creating products that are made use of as a component of other tools equipment that is utilized to generate consumer products, for the most component.

It's likewise not unusual for metal makers to bid on jobs via attracting submission, as well as if the company obtains the agreement they can begin with the drawing board of a task, including ordering materials, setting machines for the job, and also so on. The real creation of a product in conformity with a project is the following action, as quickly as the entirety of basic materials shows up and the entire fabrication store prepares.

Furthermore, there's also an additional action in this whole procedure that is executed besides of the fabrication processes are done and it's called installment, which mainly includes partially or totally assembling the requested item. Some other procedures inside of a fabrication shop may just require to be something about finishing an item it is an apart process that is secondary to steel fabrication as well as consists of sprucing up, coating, deburring, paint, etc.

An Unbiased View of Steel Fabrication Apprenticeship

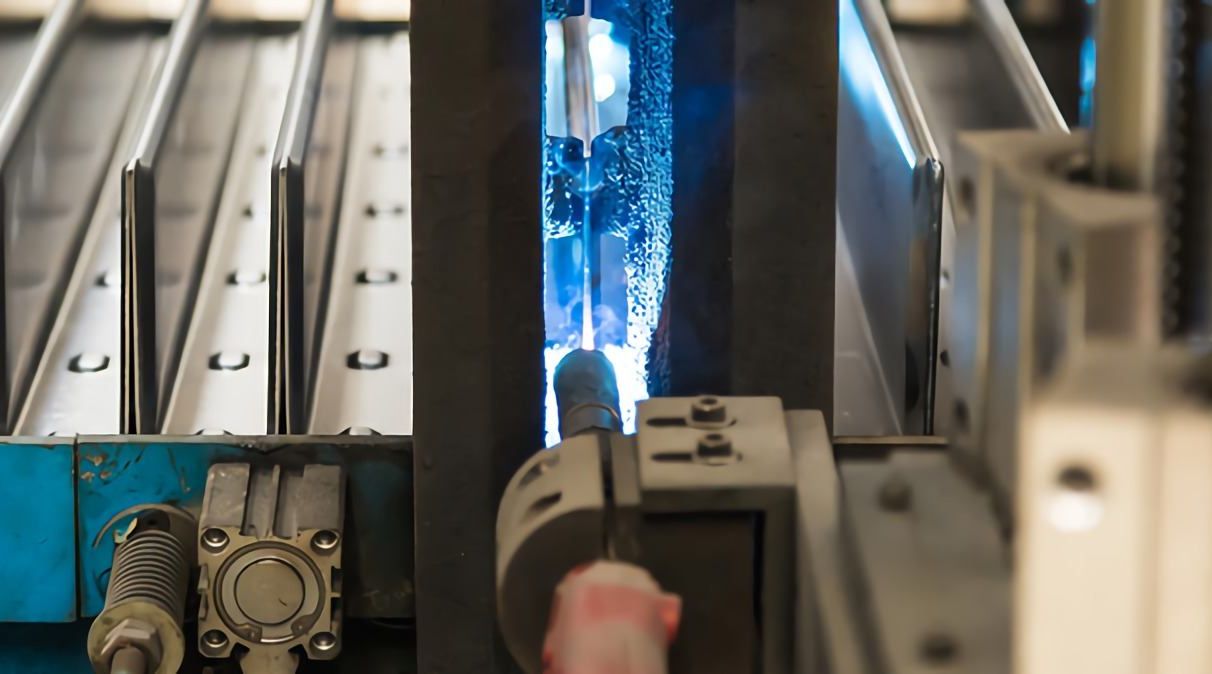

You can discover numerous different steel manufacture procedure enters the listed here: utting, Folding, Extrusion, Punching, Stamping, Casting, Drawing, Forging, Machining, Shearing, Welding. Since we're conscious of what they're called, it's time to review what each of those actually indicates, beginning with reducing. Cutting, While metal fabrication consists of a whole lot of various processes, cutting is basically one of the most usual one around.The reducing methods can be considerably different, too, including manual, power tools, computer-controlled cutting, as well as much more. There are likewise some cutting types that are extremely details in the means the cut is done. As an example, there's cutting with a die as the part that reduces off the needed component of the material.

Folding, Folding is an additional procedure that is very easy in its idea all you do is control the raw material to flex it in the preferred method. There are three major methods of folding in steel fabrication, and the most typical one is with the help of a brake press.

The Main Principles Of Fabricated Steel Angle

This process uses an especially crafted open or shut die to decrease the size check my source of a basic material item to match the size of the cross-section of the die and to form a tooth cavity inside of a material piece by pushing around a die. One of the most typical form of raw material for this operation is the form of a cyndrical tube or a metal slug.Hot extrusion is making use of an increased temperature of the material to make it more probable to be molded in a particular shape and also is mainly used for functioning with products like copper or light weight aluminum. Cold extrusion, on the other hand, is executed at space temperature and is frequently made use of for steel metal fabrication to make the product much more durable.

When the end item is the product item with holes it is used for fastening objectives. If completion item is a variety of steel pieces that were required out of the initial piece of resources, then this entire process can be certified as blanking. Marking, Marking is rather close to boxing, with the major distinction being that marking does not develop a hole in the raw product piece, but develops Get More Information a dent in a said piece.

There are 2 primary sorts of marking presses out there today mechanical and also hydraulic. In the bulk of cases, marking is performed on steel sheets with inch density or reduced, and also it produces an impressive variety of products, consisting of coins (a procedure called coining), smaller sized steel components for electronic devices (4 slide developing), as well as so on.

Not known Incorrect Statements About Steel Fabrication And Welding

It's practically a perfect procedure for making similar items using the exact same mold and mildew, particularly useful in mass-production. Of course, there are various variants of casting. For instance, pass away casting makes use of a die as a holding place for a liquified metal rather than a mold and mildew, as well as the shape of the end product is chosen by the type of a die and also by the amount of stress related to it.The end item is more powerful than with other sorts of spreading, but it also makes it way harder to eliminate the mold and mildew after the item is done cooling as well as forming. A different sort of casting can theoretically repair the trouble of eliminating the mold and mildew, called semi-permanent mold and mildew. It utilizes an expendable core in the mold and mildew to make the elimination process even more easy than with irreversible mold and mildews.

Report this wiki page